Ramadan Report – A Logistics Manager’s Guide

Table of Contents

The Holy month of Ramadan, just like any other seasonal activity, creates a surge of demand for different consumer products. Needless to say, overseeing logistics in Ramadan can be a massive challenge – especially if you’re in a high-demand industry.

Every year, supply chains across the world scramble to keep up with this spike (especially those tied to Muslim majority countries). However, the people who feel the most pressure are logistics managers.

If you’re a logistics service provider, an in-house manager, or just someone who’s curious about how companies deal with logistics in Ramadan, keep reading.

In this guide, we’ll paint a clear picture of how Ramadan affects consumer shopping, its implications, and some best-practices for our friends in logistics.

Let’s get started.

How Ramadan Affects Consumer Buying Behavior [What the Data Shows]

The festivities and the spirit of the holy month brings everyone closer.

On average, people begin to socialize more, joining their friends and families to break their fast at dusk (known as iftar).

Furthermore, observing intermittent fasting – a requirement for most Muslims – increases the demands for certain consumer products.

The million-dollar question – how do those social and cultural factors affect consumers?

Answer: They start buying more.

Most consumers prefer to buy in bulk and stock up their pantries in advance (either once in the beginning or at regular intervals throughout the month).

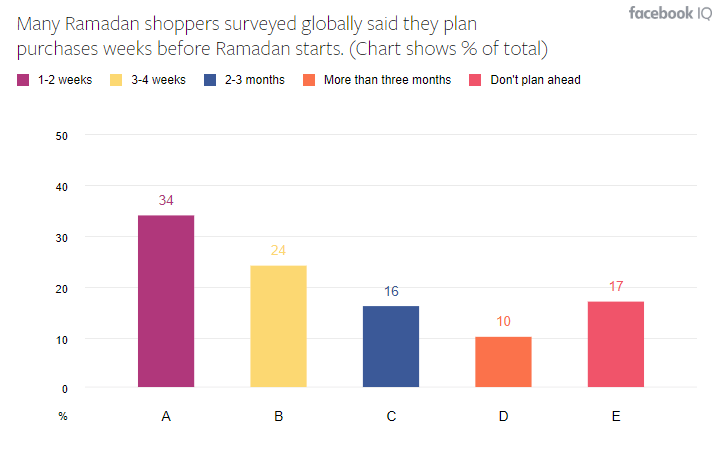

What’s more is that the majority of consumers begin their Ramadan shopping in advance.

According to Facebook IQ, out of the Ramadan shoppers surveyed globally, 34% plan their purchases 1-2 weeks before the start of Ramadan, 10% plan their purchases more than 3 months in advance, whereas 17% don’t plan ahead:

via Facebook IQ

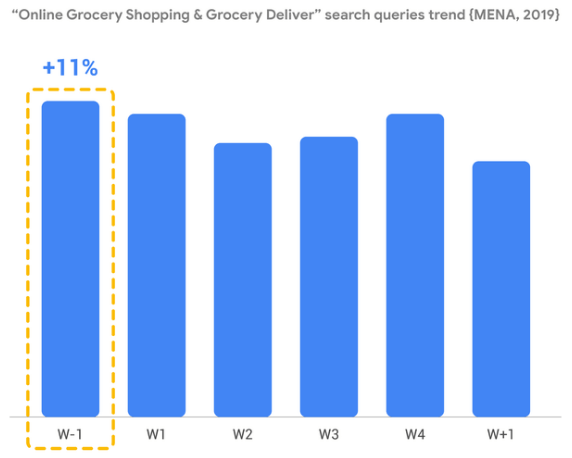

Data from Google tells a similar story. For instance, “online grocery shopping” peaks a few weeks before Ramadan.

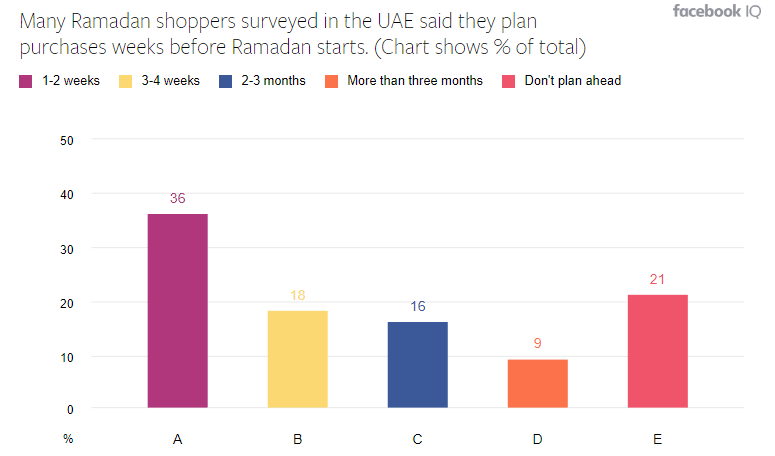

People in the Emirates aren’t so different.

Survey shows that on average, 36% of Ramadan shoppers in the UAE plan their purchases 1-2 weeks prior to Ramadan:

via Facebook IQ

Furthermore, about 41% of shoppers in the UAE report that they spend more than usual during the month of Ramadan.

And that’s just the tip of the iceberg.

The data above doesn’t account for the shopping associated with Eid al-Fitr – a significant festival celebrated by Muslims around the world to mark the end of Ramadan.

All things considered, naturally, this spike in consumer spending offers a lucrative opportunity to meet demands and cultivate customer loyalty.

However, without proper planning, contingencies, and communication, you risk losing your customers to your competitors.

What to Expect This Year

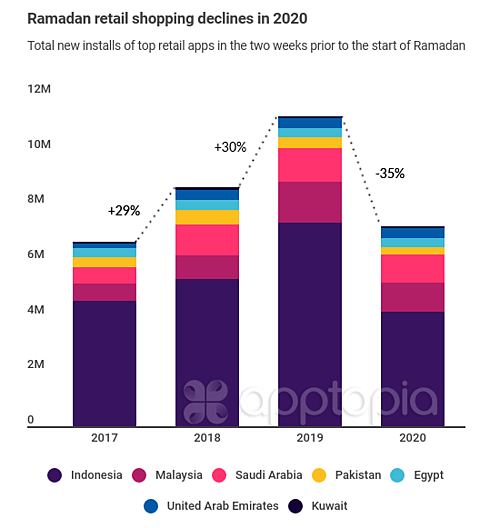

Last year, due to the pandemic, Ramadan retail took a significant dip.

We can conclude that by looking at the total number of installs of eCommerce retail apps prior to Ramadan in major Muslim countries around the world (including Indonesia, Malaysia, UAE, Saudi Arabia, Pakistan, Egypt, and Kuwait):

via Apptopia

Normally, you’d think that during a pandemic, more people would flock to online retail to avoid contact.

While that’s not entirely untrue, Ramadan retail took a dip in 2020 because people didn’t celebrate the festivities how they normally do.

But what about this year?

With multiple potential COVID vaccines on the horizon, things are generally looking up this year, and Ramadan retail is once again expected to pick up its pace.

What Does It All Mean for Logistics Managers? [A Blueprint for Smooth Sailing]

Considering the historical data, and what it all entails, as a manager, you need a sound game-plan for executing smooth logistics in Ramadan.

By implementing certain best-practices, at the right time, you’re golden.

Here’s everything you should do, in order:

1. Do Accurate Forecasting

First and foremost, you need to calculate the demand for your best-selling products or raw materials as accurately as possible.

This, in turn, will help you estimate requirements for your:

- Inventory

- Labor

- Shipments

Looking at the data of previous years can be a great starting point.

In addition, throw in external variables into the mix that might affect demand, such as change in preferences, prices, etc.

What’s more, and this is really important, you need to stay on top of what the marketing department in your company (or your partner company) is up to.

For instance, if they’re going all in on pushing certain products during Ramadan, you need to factor that in your model to accurately project demands.

All in all, maintain close collaboration with the marketing team, and stay on top of the various economic, behavioral, political, and industrial trends, and factor in everything that might affect your planning.

2. Pick an Appropriate Inventory Planning Strategy

Depending on your current labor resources, warehousing capacity, and the projected demands, there are two routes that you can take to plan your inventory for Ramadan.

In fact, these can be applied to almost every other festival/peak season (like Christmas):

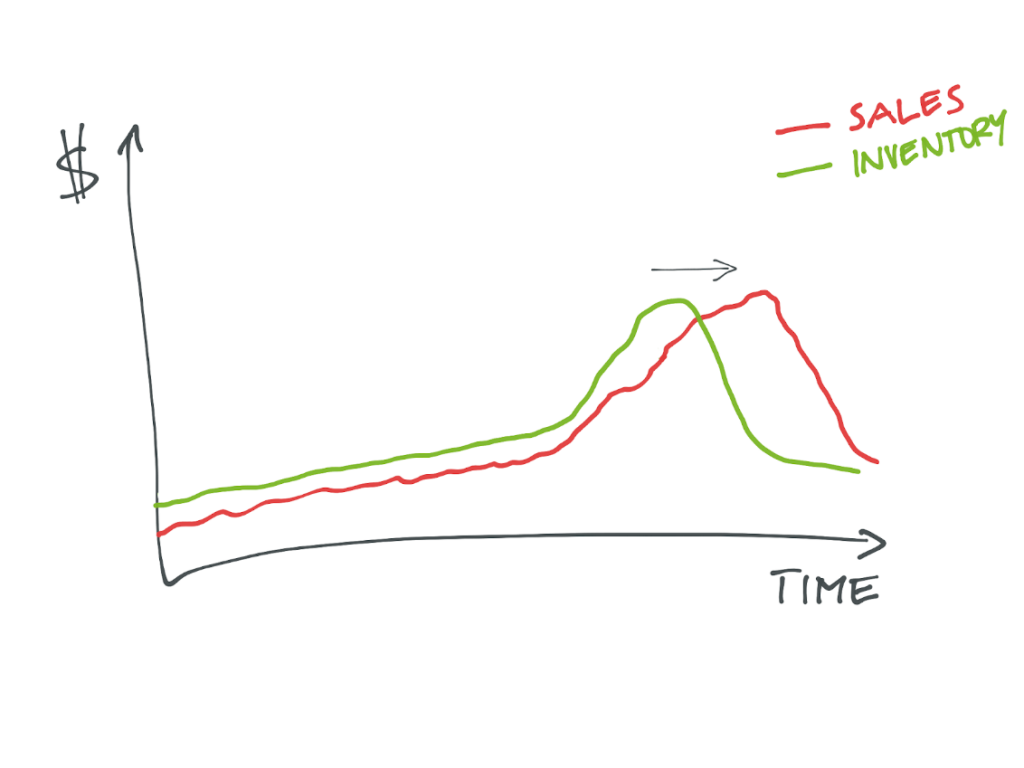

a) Purchase Later

In the purchase later strategy, you stock up closer to Ramadan (or right around when your customers typically begin shopping for Ramadan).

The goal is to wait as long as possible before stockpiling, but not too long to avoid stock-outs.

Naturally, this strategy is a bit risky. However, if executed properly, it can save you in warehousing costs as you wouldn’t be requiring any additional capacity to stockpile your goods.

However, this strategy may require you to have higher-than-usual labor resources to handle a significant inventory in a rather small timeframe.

In Ramadan, higher labor demand is a challenge in and of itself, because most companies – especially in Muslim-majority regions, like the middle east – have to cut down on their business hours. Or they have to struggle with a shortage of available resources.

Whatever the case, you should factor that in if you decide to opt for this route, and plan out your labor accordingly.

Generally, this strategy is safe if the demand forecast for the product(s) in consideration isn’t that high.

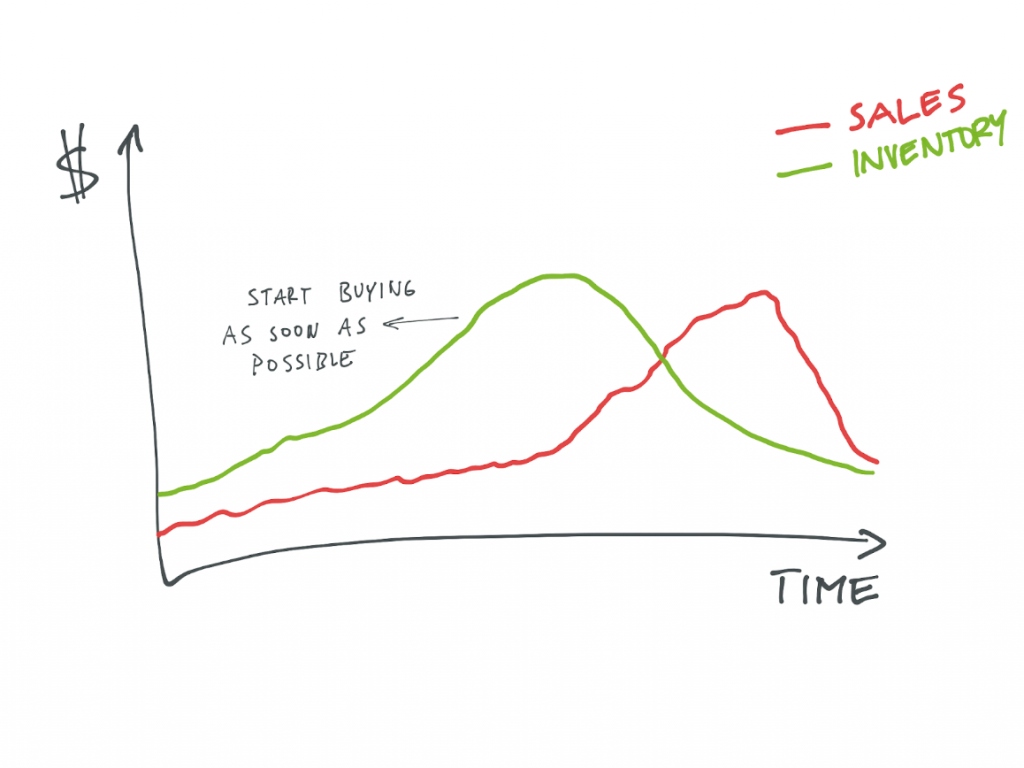

b) Purchase Early

The other option is the purchase early strategy, which, as the name suggests, involves purchasing goods in advance (for instance, a few months prior to Ramadan).

This strategy is less risky in that it can help avoid stock-outs. Even if you feel that your inventory is depleting at a faster rate than you initially anticipated, you have enough window to replenish your stocks.

Furthermore, it requires fewer labor resources than the previous strategy, which is good for Ramadan.

The only downside – this strategy requires additional warehousing capacity.

3. Take Shipment Emergencies/Delays into Account

Regardless of which strategy you opt for, you need to factor in shipment delays when planning things out.

There’s always a huge risk of delays.

And needless to say, during a peak season such as Ramadan, even the slightest delay could be catastrophic for sales and revenue.

For that reason, you need to have some wiggle room in your plan – especially if you opt for the purchase later strategy for inventory planning.

Furthermore, your overall logistics management process needs to be highly dynamic and flexible. This entails:

- Maintaining close communication with partners

- Tracking orders and shipments in real-time

- Leveraging data to extract insights and using it to improve your supply chain

- Using predictive analytics to determine surges and drops in demand

Having a dynamic and flexible process will not only help you in keeping up with shipment delays, but also equip you to handle sudden demand surges resulting from marketing initiatives.

Easy Solution: Look for a Reliable and Transparent Freight Forwarder

Even if you hire the most reliable freight forwarder, the risk of delays will always be there.

The risk itself isn’t the problem.

What you need is a reliable freight forwarding/logistics company that’s transparent, efficient, keeps you up-to-date regarding shipment delays, and takes other tasks off your plate, such as customs and clearance.

Qafila ticks all of those boxes, and more. We are a technology-driven freight forwarding service, offering air freight, land, and sea freight services (with the options of both FCL and LCL).

Our platform delivers real-time visibility, actionable insights, automation of execution, and more. Learn more about our services to see how we can help out with your logistics in Ramadan.

4. Communicate Clearly When Handling Stock-Outs

Stock-outs happen to the best of us.

No matter how much effort you put at projecting, planning, and just being proactive, unforeseen circumstances can throw you off your trajectory.

However, you can minimize that risk.

To that end, it is extremely crucial that you keep all the concerned departments and/or partners in the loop about everything, including:

- Your demand forecasts

- Purchasing requirements

- Labor requirements

- Warehousing requirements

- Potential shipment delays

The key is to maintain close communication with everyone directly involved with your business, including your supplier(s) of raw material/products, shippers/third-party logistics company (if any), and the marketing and customer service department.

And that communication should go both ways. For instance, if marketing anticipates any shift in demand, whether due to a viral campaign or some external factor, logistics should be kept in the loop.

This is also especially true for freight forwarders as they are a crucial link in logistics communications.

This will help you minimize the risks of stock-outs. Furthermore, it will help you prepare for stock-outs in advance, allowing you to communicate potential shortages beforehand with your customers, come up with solutions, and retain them in the process.

Ending Note

If there’s any time where you want to test your logistics management process, it’s the month of Ramadan.

All in all, the secret sauce for capitalizing on all the positioning and conversion opportunities that it has to offer is having a proactive approach, ample planning for the peak, and close communication throughout the month.

As a final piece of advice, we’ll leave you with this – regardless of your strategy, it’s always better to kick-start your shipments at least 2 weeks prior to Ramadan.